Pearldrill 9 1/2" (241.3mm) Tricone Hard Rock Drill Bit Oil Water Gas Well Drilling Equipment Tungsten Carbide Drill Bit

Tricone bits mian model Note: Please do not select the maximum value for WOB and rotational speed at the same timeCuttin

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | IADC537 |

| Condetion | New |

| Application | Energy & Mining, Well Drilling |

| Video Outgoing-Inspection | Provided |

| Brand Name | Pearldrill |

| Machine Type | Drilling Tool |

| Processing Type | Forging |

| Size | 9 1/2′′, 241.3mm |

| Bearing Type | Rubber Sealed Bearing/Metal Bearing |

| Usage | Well Drilling |

| Machinery Test Report | Provided |

| Place of Origin | China |

| API | 2 3/8"~7 5/8" |

| Weight(Kg) | 15 |

| Formation | Soft, Medium Soft, Hard, Medium Hard, Very Hard |

| Applicable Industries | Building Material Shops, Construction Works, Ener |

| Transport Package | Original Package with Wooden Cases |

| Specification | 45*45*50CM |

| Trademark | Pearldrill |

| Origin | China |

| HS Code | 82071990 |

| Production Capacity | 2000piece/Pieces Per Month |

Product Description

Tricone bits mian model| IADC | Rock formation | WOB (KN/mm) | PRM(r/min) |

| 417/427/437 | Low compressive strength, high drill-ability and extremely soft formation, like shale, clay, sandstone, conglomerate etc | 0.35~0.90 | 140~70 |

| 447 | Low compressive strength, high drill-ability and soft formation, like shale, clay, sandstone, soft limestone, salt rock, plaster etc. | 0.35~1.00 | 140~60 |

| 517 | Low compressive strength, high drill-ability and soft formation, like shale, clay, sandstone, soft limestone, salt rock, etc | 0.35~1.05 | 120~50 |

| 527 | Soft formation with low compressive, like Low compressive strength, high drill-ability and soft formation, like shale, clay, sandstone, soft limestone, salt rock, anhydrite etc. | 0.35~1.05 | 120~50 |

| 537/547 | Low compressive strength, medium hard formation with hard abrasive interlayer, like Hard shale, anhydrite, soft limestone, sandstone, dolomite with mezzanine, etc. | 0.50~1.05 | 110~40 |

| 617/627 | High compressive strength, medium hard and thick hard interlayer, like hard shale, limestone, sandstone, dolomite, etc. | 0.50~1.05 | 80~40 |

| 637/737 | High compressive strength, medium hard and high abrasive formation, like limestone, dolomite, sandstone, chert, etc. | 0.7~1.20 | 70~40 |

The wear-resistance of the teeth is enhanced with premium tungsten carbide hardfacing on the tooth surfaces for the steel tooth bit.The durability of premium tungsten carbide inserts is improved with new formulas and new techniques for insert bitGauge StructureMultiple gague protection with gauge trimmers on the heel and gauge inserts on the gauge surface of the cone,tungsten carbide inserts and hardfacing on the shirttail increases gauge holding capacity and bearing life.Bearing StructureHigh precision journal bearing with two thrust faces,Balls lock the cone.Hardfaced head bearing surface.Cone bearing inlaid with friction-reducing alloy and then silver-plated.Abrasion resistance and seizure of the bearing are improved.and suitable for high rotary speedSeal and LubricationThe advanced metal seal package consists of two metal seals and two elastic energizers.Compressed energizers ensure good contact being kept on two sealing surfaces of metal rings by elastic force,and achieves the bearing seal.In the drilling,metal seals are relatively dynamic,and the energizers are static.This will improve the reliability and durability of bearing seal.The pressure compensator system and advanced grease can greatly increase the lubricating reliability.

-COMPANY PROFILE-

PEARLDRILL is a leader in the manufacture and development of many kinds of bits in China. We provide the best quality PDC coring drill, DTH drill, Tri drill bits etc to the market, all types of non-coring or coring drill traces. Our drill bits are used for well drilling, mining and construction contractors. Our drill bit has been tested and verified by time, with wear resistance and fast drilling speed. Different drill bits can be customized according to different rock formations. The engineering time is greatly shortened, and the maximum performance is exerted in the operation during drilling. Our products are durable and reliable. Our products are the preferred drill bits for drilling engineers in many countries because of our precise design and efficient drilling during use.Main product

-WHY CHOSE US-

--The first-class engineers of tricone bits and PDC bits--Advanced technology and Equipment, International standard.--R&D center for rock drilling tools, high precision CNC machines, SGS&ISO Certified.--10+ Years & 40+ Countries of service experience.--Optimized solutions for the various requirements.DIY customization: please provide your rock formation information or detailed size drawings.

Free samples: some samples can be provided free of charge.

Payment:T/T L/C,D/A,D/P,Western Union,MoneyGram.

| Packaging |

| Wood BoxFumigation Tray if necessaryOther special package can be appliedaccording to customer's need |

| Delivery |

| Prepared to deliver within 1 week, if in stockDepends on order quantity, when out of stockTransportation:By sea or air |

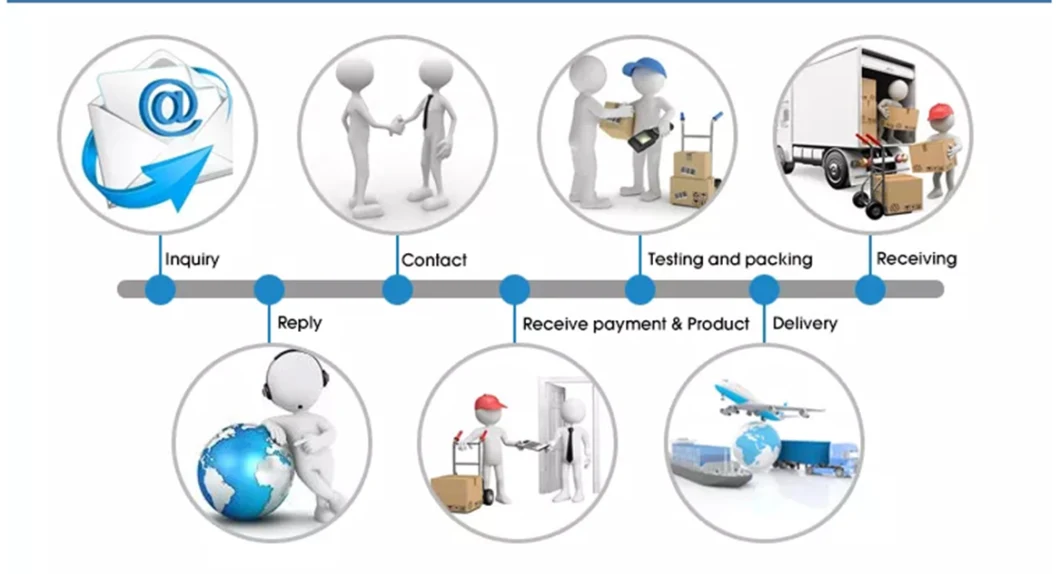

Purchase process

Related Products

-

![High Quality Mining Machine Parts, Steel Body PDC 3 Wings Drill Bit, Factory Customization 140mm PDC Diamond Bit Water Well Drill]()

High Quality Mining Machine Parts, Steel Body PDC 3 Wings Drill Bit, Factory Customization 140mm PDC Diamond Bit Water Well Drill

-

![Wholesale Manufacturers Custom Carbide Tungsten Pilot Twist Drill Bit for Drilling]()

Wholesale Manufacturers Custom Carbide Tungsten Pilot Twist Drill Bit for Drilling

-

![PDC Core Bits for Oil Drilling]()

PDC Core Bits for Oil Drilling

-

![Custom CNC Machining Plastic Fork Wrap Guards Road Bike Cycling MTB Front Frame Protective Covers Guard Protector Bicycle Part]()

Custom CNC Machining Plastic Fork Wrap Guards Road Bike Cycling MTB Front Frame Protective Covers Guard Protector Bicycle Part