Coal Power Plant Flame Retardant Belt Conveyor Loading Point Material Impact Bed Mining Machinery Parts

Overview Package size per unit product 100.00cm * 100.00cm * 100.00cm Gross weight per unit product 50.000kg Product Des

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | Custom Size |

| Standard | AISI, ASME, BS, ANSI, JIS, GB, GOST, ASTM, DIN |

| Surface Treatment | Polishing, Without Processing |

| Manufacturing Process | Forging |

| Material | Uhpwme+Rubber, Rubber |

| Type | Belt Conveyor System |

| Structure | Belt Conveyor |

| Energy Saving | Energy Saving |

| Customized | Customized |

| Material Feature | Impact Absorb |

| Color | Red, White, Black, Blue |

| After-Sales Service | 1 Year |

| Rubber Color | Black |

| Hardness | 696~98 Shore a |

| Application | Coal Mining, Power Plant, Port, Heat-Engine Plant |

| Length | 1000 / 1220 / 1400 mm, etc |

| Width | 100 mm |

| Height | 50 / 75 / 100 mm |

| Usage | Material Handling Loading Point |

| Transport Package | Plywood Case, Wooden Case, Pallet |

| Specification | Customized |

| Trademark | HT |

| Origin | China |

| HS Code | 8431390000 |

| Production Capacity | 5000 Pieces/Month |

Packaging & Delivery

Package size per unit product 100.00cm * 100.00cm * 100.00cm Gross weight per unit product 50.000kgProduct Description

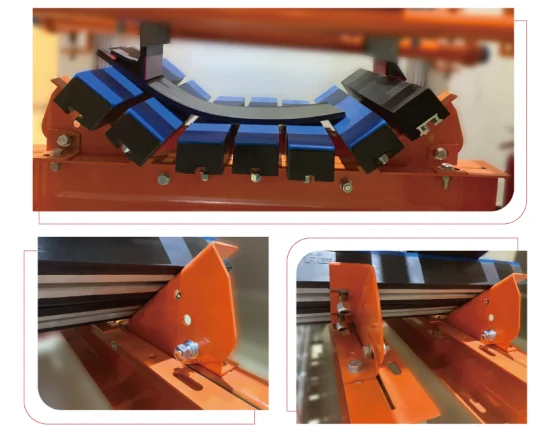

The buffer bed is composed of a buffer strip as a metal support, in which the buffer strip is composed of flame retardant and antistatic and the combination of buffer rubber and metal skeleton, which is suitable for ground and underground coal mine environment.The surface of the buffer strip adopts ultra-high molecular weight polyethylene, which has the characteristics of flame retardant and antistatic, high wear resistance, impact resistance and self lubrication. It can withstand the impact of loaded materials and the friction of the conveyor belt during operation, and will not cause damage to the conveyor belt and increase the additional power.It is installed under the belt at the unloading point of the belt conveyor and is a replacement product of the buffer idler. It is mainly used to support and protect the conveyor belt, which can effectively buffer the impact of falling materials on the conveyor belt, prevent the damage of the conveyor belt caused by material impact and prevent the conveyor belt from deviation.Product Parameters

| Model NO. | CUSTOMIZED | Warranty | 1 Year |

| Color | Multi Color | Customized | Customized |

| Condition | New | After-sales Service | Video Technical Support/Online Support |

| Product Name | UHMWPE Conveyor Impact Bar | Features | High Wear Resistant & Good Sealing |

| Application | Coal Mining, Power Plant, Port, Heat-Engine Plant | Local Service Location | Russia, Canada, the United States, Mexico and Argentina |

| Length | 1000 / 1220 / 1400 mm, etc | Width | 100 mm |

| Height | 50 / 75 / 100 mm | Transport Package | Plywood Case, Wooden Case, Pallet |

| Usage | Material Handling Loading Point | Specification | Customized |

| Trademark | XTHT | Origin | China |

| Production Capacity | 5000 Pieces/Month |

Product Size

| Order No. | Length.mm | Width.mm | Height.mm |

| HT-IB-600 | 600 | 100 | 50/75/100 |

| HT-IB-700 | 700 | 100 | 50/75/100 |

| HT-IB-750 | 750 | 100 | 50/75/100 |

| HT-IB-800 | 800 | 100 | 50/75/100 |

| HT-IB-900 | 900 | 100 | 50/75/100 |

| HT-IB-1000 | 1000 | 100 | 50/75/100 |

| HT-IB-1220 | 1220 | 100 | 50/75/100 |

| HT-IB-1400 | 1400 | 100 | 50/75/100 |

| HT-IB-1500 | 1500 | 100 | 50/75/100 |

| HT-IB-1600 | 1600 | 100 | 50/75/100 |

| HT-IB-1800 | 1800 | 100 | 50/75/100 |

| HT-IB-2000 | 2000 | 100 | 50/75/100 |

Product Advantages

The special ultra-high molecular weight polyethylene material reduces the friction coefficient between the conveyor belt and the buffer strip to the minimum, and has good wear resistance, greatly extending the service life of the belt and the buffer strip. The buffer layer adopts excellent high elastic buffer rubber to fully and effectively absorb the impact force when the material falls, greatly reducing the impact of the material on the conveyor belt, truly improving the stress condition of the blanking point, and reducing the impact wear of the beltThe best supporting and buffering structure of the material transfer point is adopted to effectively ensure that the conveyor belt is in contact with the impact surface face to face, and the stress is uniform, preventing the longitudinal tearing of the belt caused by the breaking and falling off of the buffer idler, and greatly reducing the probability of the longitudinal tearing of the belt caused by the penetration of iron parts or sharp materials.Detailed Photos

Packaging & Shipping

Our Advantages

FAQ

Q: Are you a trading company or manufacturer ?

A: We are a manufacturer with specialized production equipments and testing machines.

Q: Can I get a sample for testing ? How do it charged ?

A: Yes, the sample is free of charge, but we don't bear the Express costs.

Q: What is the advantage of XTHT compared to other companies in the industry?

A:Our company has advanced automated production lines, uniform and stable quality, to achieve sustainable and efficient professional production. We also have rich experience in R&D and production team, can provide customers with the highest quality products and quality services

Q: What is the price policy of your company?

A: In our company, the price is different according to the quantity of your order, the more the cheaper. For more detailed information, please contact our customer service representatives. The professional team will offer you 24/7 service

Q:What are the features of the services your company offered?

A: Based on the wide range of our products, We can offer first-class one-stop sourcing service. It will improve your efficiency significantly and be more economical

Q: Can you manufacture the different Conveyor equipment products according to the customer's drawings or samples?

A: Yes, we can develop the new products as the customer's request,such as Impact bed,belt cleaner,rubber and polyurethane products,etc

Q: Do you have foreign experience for your products?

A: Yes, we have exported our products to USA , Australia, German, Korea ,UK, The Philippines, Indonesia,etc.